The growing trend for the consumption of healthy food, and thus fresh vegetables and fruits, has put a huge challenge for producers of food products, because the products delivered to the consumer must maintain the highest quality and freshness for as long as possible.

The right way of packing has a huge impact on extending the shelf life, and thus preserving the nutritional value of vegetables and fruits in an unchanged form as long as possible. If the appropriate temperature is maintained during the distribution and storage process and optimal packaging is used, it is possible to delay the aging of fruit and vegetables and extend their shelf life by up to 800% [1].

The most important parameters influencing the extension of the use-by date are temperature, humidity and the protective gas atmosphere used in the packaging [1].

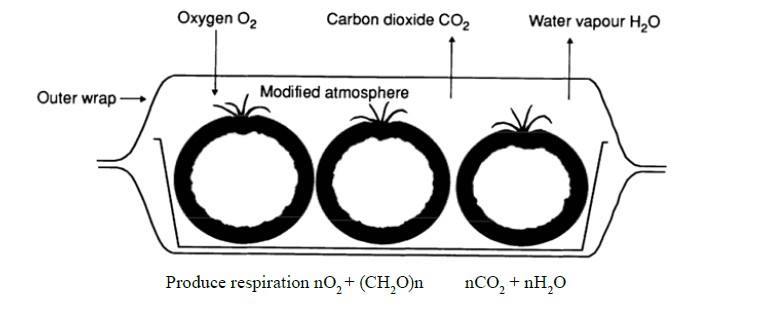

Vegetables and fruits are products that undergo various biological processes, such as ripening and aging. These processes continue even after the harvest. During the ripening and aging processes, vegetables and fruits breathe, which results in the consumption of oxygen and the production of carbon dioxide and water.

Figure 1. Biochemical and physical processes occurring in a modified atmosphere pack (Paine and Paine, 1992) [2].

Figure 1. Biochemical and physical processes occurring in a modified atmosphere pack (Paine and Paine, 1992) [2].

Types of perforation

Breathing intensity varies from product to product and is known as the respiration rate (RR). That is why it is so important to select and use the appropriate packaging and atmosphere adapted to the requirements of various products.

In order to ensure proper gas exchange between the environment inside the package and the atmospheric air outside the package, various types of foil perforations are used. Due to the size of the holes, the perforation can be divided into micro perforation, where the diameter of the holes is 50-200 µm, and macro perforation, when the diameter of the holes exceeds 200 µm [3,4,5]. Due to the technology used, perforation can be divided into laser perforation, thanks to which we can obtain both micro and macro perforation and mechanical and pneumatic perforation used to obtain larger holes.

Macroperforation

Macro perforations are used for packing products that require high air circulation. It ensures free air flow inside the package. It protects and protects products such as tomatoes against mechanical damage, while ensuring the removal of moisture from the packaging. In this type of perforation, holes with a large diameter from 4 mm to 8 mm are used.

Macro perforation with a diameter of 200 – 500 µm made with a laser is used for products that require greater protection against external factors, but at the same time still need a large air exchange, oxygen supply and discharge of accumulated water vapor and carbon dioxide to the outside. This type of packaging does not use a modified atmosphere due to too much air exchange between the internal and external environment. This type of macro-perforated film is used for products with an undamaged outer structure which, thanks to their continuity, are not prone to rapid deterioration. Such products include, among others whole leaves of spinach or arugula.

MAP and microperforation

Products that are highly susceptible to deterioration and oxidation processes require the use of a modified atmosphere. Increasing the carbon dioxide content with the minimum concentration of oxygen reduces the oxidation processes and inhibits the growth of microorganisms. In order to minimize the risk of anaerobic conditions inside the packaging, it is necessary to properly select packaging materials that, thanks to their properties, will allow the penetration of oxygen inside and carbon dioxide and water vapor outside the packaging. The best solutions for this application are films with a high gas and permeability coefficient of the polymeric film Pi (gas and permeability coefficient of the polymeric film) and an appropriate gas and transsmision rate TRi [4]. In order to ensure the proper degree of “breathing” of the packaging, films with properly made micro-perforation are used.

SUMMARY

The packaging market gives us great opportunities to choose the perfect solution. When making a choice, we must always be guided by the properties of the food for which the packaging will be dedicated. Its structure, technological processes, respiration rate, temperature and humidity in which it will be stored and distributed are important. Only if you have sufficient knowledge about the features of the product, you can design the optimal packaging for it.

Many years of experience allow our experts to create and choose the right solutions for food products. Your products deserve the best packaging.

[1] Danish Technological Institute „Packaging and Transport” 2008.

[2] Paine, F. A., & Paine, H. Y. (Eds.). (1992). A handbook of food packaging. Springer Science & Business Media.

[3] González-Buesa, J., Ferrer-Mairal, A., Oria, R., & Salvador, M. L. (2012). Alternative method for determining O2 and CO2 transmission rates through microperforated films for modified atmosphere packs. Packaging Technology and Science, 26, 413–421.

[4] Gonzalez, J., Ferrer, A., Oria, R., & Salvador, M. L. (2008). Determination of O2 and CO2 transmission rates through microperforated films for modified atmosphere packaging of fresh fruits and vegetables. Journal of Food Engineering, 86, 120–194.

[5] Lange, D. L. (2000). New film technologies for horticultural products? HorTechnology, 10(3), 487–490.