We create a new dimension of packaging

The most important thing in our work is development and creative view. Many years of experience and practice as well as specialist knowledge of engineers allow us to support our Partners at every stage of the project

R&D

Research and development allow us to improve the proposed solutions. Before we launch a product, it undergoes many tests to guarantee safety and the highest quality. We are constantly looking for innovative raw materials and we are developing new recipes to meet the expectations of the most demanding Partners.

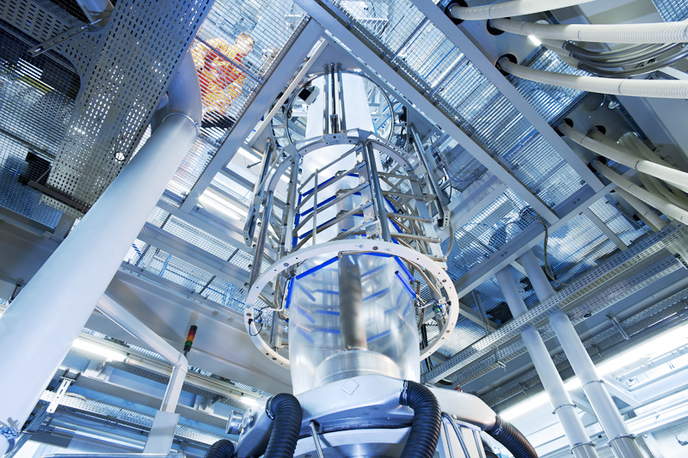

Foil extrusion

The most modern technologies used for the production of film by the blow method allow you to create products tailored to the needs of our partners. Technologists select the right raw materials and using the right parameters we get a film with different mechanical properties, ideal even for demanding products.

Knitting machines

Well-equipped machine park allows us to meet even the most demanding needs of our partners. Depending on expectations, we can make precise cuts and easy open cuts. The acquired knowledge and many years of experience allow the use of anti-fog technology, thanks to which fresh products look more attractive in packaging. We also make 2- and 3-layer laminates in solvent-free technology. Synergy of knowledge and modern technologies.

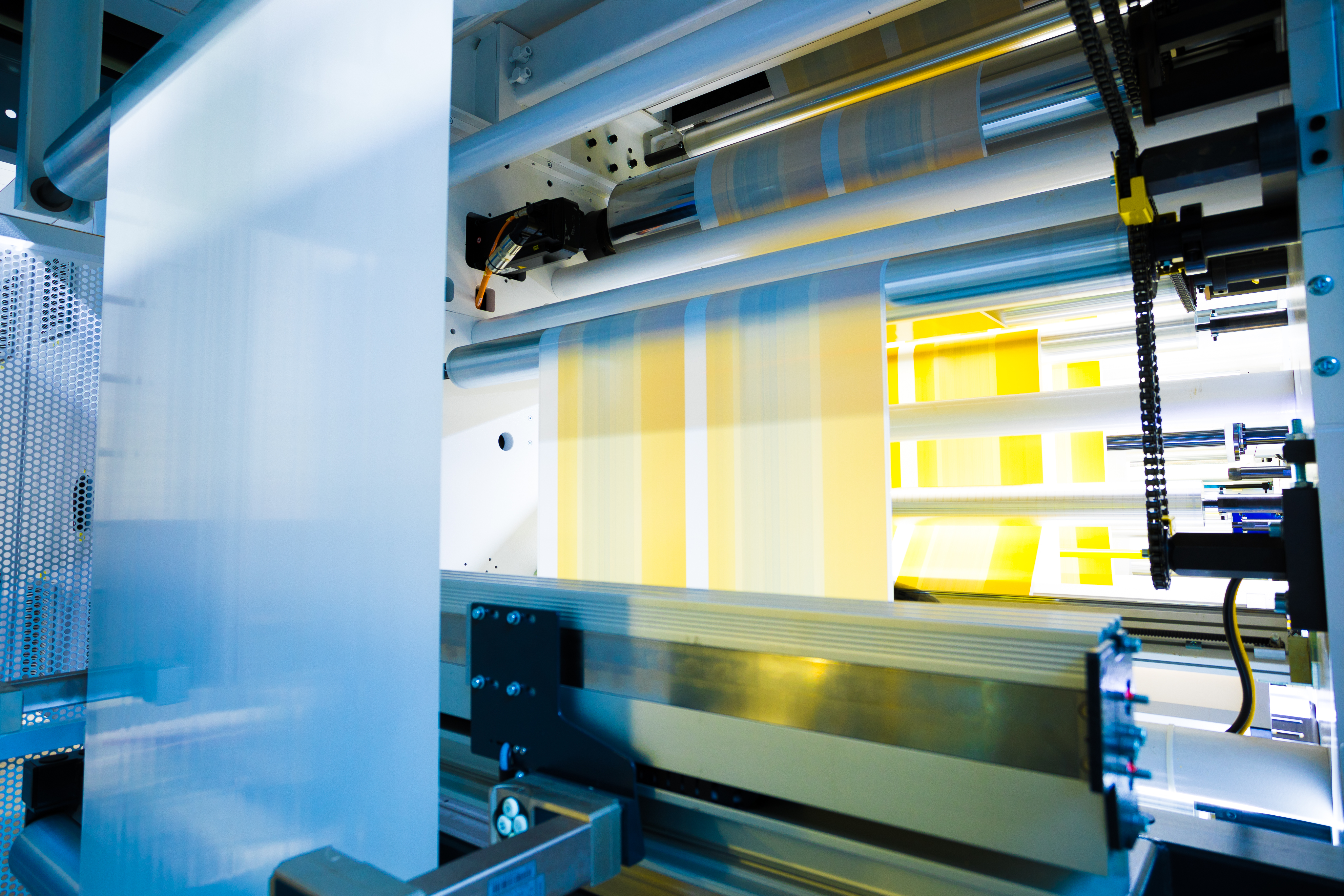

Flexographic prepress

Own graphic studio allows you to design an attractive packaging from scratch. We also prepare materials for flexographic printing sent by Partners. We offer support at every stage – from graphic design customization to the production of photopolymer printing matrices. Thanks to this, the process of implementing the new design is very efficient. Trust our experience and together we will work out the best solution.

Surgical precision of printing

Thanks to world leaders in the field of technology, our printing house is equipped with a top-class machine park. It provides a wide range of possibilities. The machines have a print inspection system, thanks to which we have full control over the process, which minimizes the risk of any errors. In addition, we have a computer paint mixing plant and a color management system for the best and repeatable results. All prints can be made in HD Flexo technology, which allows you to print the highest quality.

Lamination and packaging

Well-equipped machine park allows us to meet even the most demanding needs of our partners. Depending on expectations, we can make precise cuts and easy open cuts. The acquired knowledge and many years of experience allow the use of anti-fog technology, thanks to which fresh products look more attractive in packaging. We also make 2- and 3-layer laminates in solvent-free technology. Synergy of knowledge and modern technologies.

Quality control

At each stage of the production process, our products are subjected to thorough control. We have implemented a quality management system based on the requirements of the BRC Packaging and Packaging Materials standard. This certificate guarantees the highest and repeatable quality and safety of the packaging produced, which has a huge impact on food products.